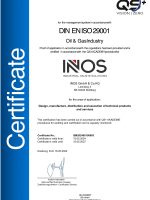

At INOS GmbH & Co.KG, quality and certifications are our highest priorities.

In addition, our employees have the following recognized training and certifications:

A specialized provider of engineered in-service leak sealing solutions for pressurized and critical process systems. Utilizing advanced sealing compounds, custom-designed enclosures, and validated application methodologies, the company restores containment integrity under operating pressure, minimizing unplanned downtime and maintaining process continuity in demanding industrial environments.

An environmental management system is a collection of processes, rules, and measures that enable a company to systematically:

identify its environmental impacts (e.g., energy consumption, waste, emissions), set environmental targets (e.g., reduced CO₂ emissions), plan and implement measures, regularly monitor whether the targets are being met, and continuously improve. The most well-known system is based on DIN EN ISO 14001.

DIN EN ISO 45001 is an internationally recognized standard for occupational health and safety management systems. It helps organizations create safe and healthy working conditions, prevent work-related injuries and illnesses, and systematically meet legal and other requirements.

DIN EN ISO 14001:2015 is an international standard for environmental management systems.

It specifies requirements that enable organizations to systematically improve their environmental performance, reduce environmental impacts, comply with legal obligations, and define as well as monitor environmental objectives.

The standard is applicable to organizations of all sizes and sectors and supports a continuous improvement process with a focus on sustainability.

DIN EN ISO 45001 is an internationally recognized standard for occupational health and safety management systems. It helps organizations create safe and healthy working conditions, prevent work-related injuries and illnesses, and systematically meet legal and other requirements.

DIN EN ISO 9001:2015 is an international standard for quality management systems (QMS).

It specifies requirements that enable organizations to systematically control their processes, increase customer satisfaction, and ensure continuous improvement.

DIN EN ISO 29001 is an international standard for quality management systems in the oil, gas, and petrochemical industries.

It builds upon ISO 9001 and supplements it with industry-specific requirements, such as those related to risk management, supply chain security, traceability, and non-compliance.

The standard aims to improve product and process quality, minimize risks, and ensure reliability throughout the entire supply chain.

DIN EN ISO 29001 is an international standard for quality management systems in the petroleum, petrochemical, and natural gas industries.

It is based on ISO 9001 and extends it with industry-specific requirements, such as risk management, supply chain integrity, traceability, and defect prevention.

The aim of the standard is to improve product and process quality, reduce risks, and ensure reliability throughout the entire supply chain.

The SCC certificate demonstrates that processes for planning, controlling, and monitoring the supply chain are implemented in a structured, transparent, and efficient manner. It encompasses, among other things, material flow, logistics, production supply, and risk management processes and serves as proof of quality, reliability, and compliance for partners and customers.

The system for transferring material identification serves to identify materials unambiguously, in accordance with standards, and in an internationally understandable manner. It ensures that a material’s designation is correctly passed on from production through processing to application. This standard-based assignment ensures that properties such as chemical composition, mechanical characteristics, and delivery condition are unambiguously referenced.

The WHG specialist company certificate confirms that a company meets the legal requirements of the German Water Resources Act (WHG). It certifies the professional execution of work on facilities handling substances hazardous to water (e.g., manufacturing, installation, maintenance, cleaning, or decommissioning). The aim is to protect surface water and groundwater through qualified personnel, appropriate organization, and certified work procedures.

This certificate confirms that the company possesses the professional qualifications, suitable equipment, and practical experience in leak sealing on pressurized systems. The company is trained to locate and seal leaks safely, efficiently, and without system downtime. Applicable safety regulations, quality standards, and recognized technical rules are adhered to.