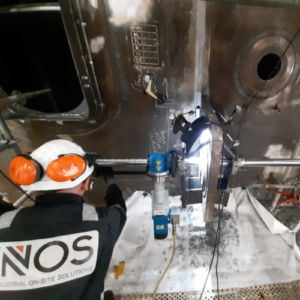

Spindle Machine

A spindle machine is a machine tool mainly used for machining workpieces by rotating the spindle. Here are some general features and functions that might be included in the description of a spindle machine:

1. Spindle:

The spindle is the central component of the machine and carries the tool.

It is a rotating shaft that provides the necessary cutting speed for machining.

2. Workpiece holder:

A chuck or other device for securely attaching the workpiece to the spindle.

3. Tools:

Tools such as drills, milling cutters or cutting tools are attached to the spindle and are used to machine the workpiece.

4. Control system:

Modern spindle machines are often equipped with computer-aided control (CNC) systems that enable precise movements of the spindle and other components.

5. Movement axes:

The spindle machine can have multiple axes of movement depending on its configuration. This enables precise positioning of the tool relative to the workpiece.

6. Work area:

The area in which the machine can work, defined by the freedom of movement of the various axes.

7. Cooling system:

A cooling system that uses coolant to control temperature during the machining process and extend tool life.

8. Powerful Drive:

A motor or drive system that provides enough power to operate the spindle and other moving parts efficiently.

9. Clamping devices:

Devices for fixing and stabilizing the workpiece during the machining process.

10. Safety devices:

Safety devices to prevent accidents, such as emergency stop switches and guards.

11. Material removal:

The spindle machine removes material from a workpiece to achieve the desired shape, size or surface finish.

Contact:

Divisional Sales Manager

Tel.: +49 (0) 2402 / 90 20 167

Mobil: +49 (0) 176 629 676 29