IN THE FIELD OF ENGINEERING, INOS REQUIRES MANY YEARS OF EXPERIENCE AND SKILLS.

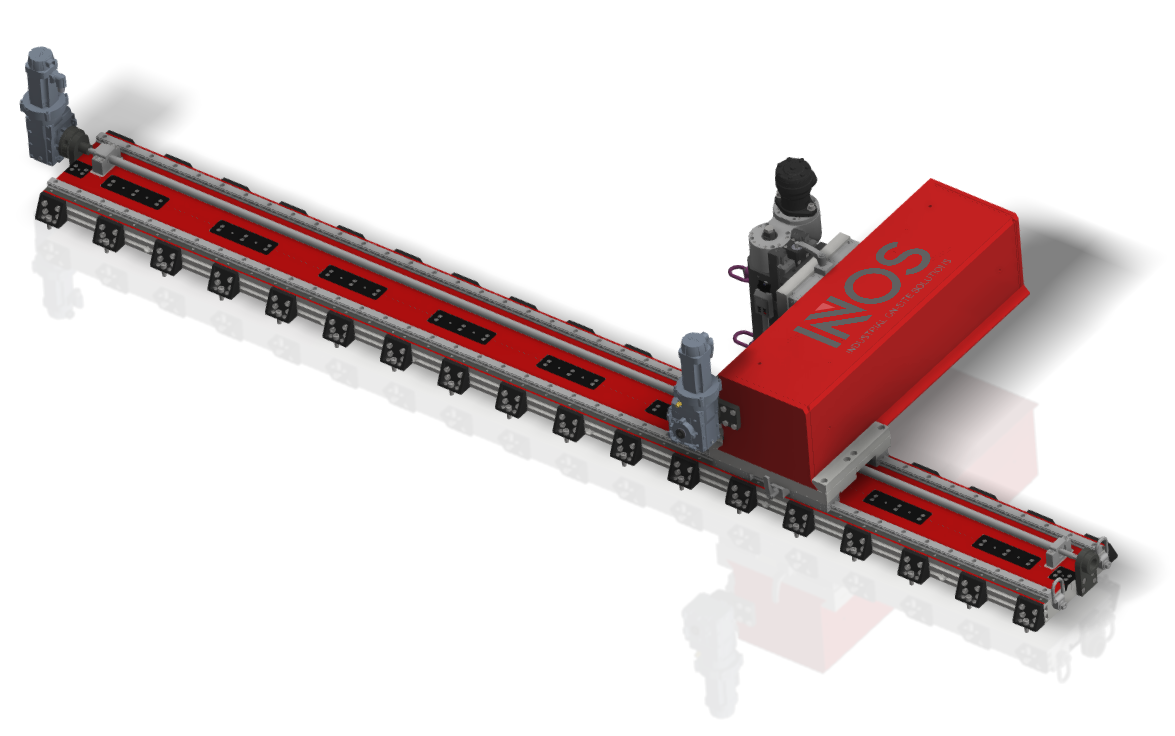

Thanks to many years of experience in various industrial sectors, INOS builds transportable machine tools with a high degree of automation, which ensures the quick installation of the machine and the safety of the employees. The set-up time and processing quality are the top priorities. The design, manufacture and commissioning of the machines is carried out by the INOS Group’s own staff.

Engineering service INOS

FEM calculation:

For checking existing or newly designed components, INOS uses the calculation with the help of the finite element method (FEM). For this purpose, occurring forces, moments or displacements are applied to the component and the resulting forces are analyzed. The analysis provides information about the geometry of the component, which can then be further optimized. This means that components can be designed lighter and smaller and the forces can still be absorbed.

In addition, a fatigue and natural frequency analysis can be carried out for each component. As a result, a failure of the component due to several repetitive load cases or when excited in the natural frequency can be ruled out.

3D laser scan:

INOS uses 3D laser scanning technology to check the position and shape tolerances of various components. This means that components can be scanned in just a few steps and then evaluated. Defectively manufactured components can be identified quickly and sources of error minimized.

In addition, the technology of 3D laser scanning can be used in the field of reengineering if, for example, old drawings of spare parts cannot be found. The spare part is scanned, evaluated and designed. By using the 3D laser scan, tolerance deviations can be reduced to a minimum and the dimensions can be reproduced in detail.

Torque calculation of flange connections according to TA-Luft:

The TA-Luft administrative regulation came into force in December, which stipulates that flange connections must be “technically tight.” This requires proof that the flange connection is leak-tight, with a specified maximum leak rate.

INOS offers calculations of bolt torque, seal contact pressure, and leak rate according to TA-Luft (DIN EN 1591-1). The calculations are fully documented and made available to the customer.

In addition, if required, the flange assembly is carried out by employees of INOS GmbH & Co. KG and fully documented, with acceptance of the flange through 3D scans and subsequent analysis.